Views: 0 Author: Site Editor Publish Time: 2025-01-24 Origin: Site

When it comes to manufacturing and industrial applications, materials with high durability, impact resistance, and versatility are highly sought after. One such material that has been widely used in a variety of sectors is the light guide ABS plastic sheet. This type of sheet is specifically designed to offer numerous benefits, including strength, flexibility, and resistance to environmental factors like moisture and chemicals. In this article, we will explore what a light guide ABS plastic sheet is, its unique features, applications, and why it is an ideal choice for various industries.

An ABS plastic sheet is made from Acrylonitrile Butadiene Styrene (ABS), a highly durable thermoplastic known for its strength, toughness, and resistance to chemicals and impacts. ABS plastic is widely used in many industrial and consumer applications due to its excellent processing properties, making it easy to fabricate, drill, and mold.

A light guide ABS plastic sheet is a specialized form of this material. As the name suggests, it is engineered to efficiently guide light across its surface. This feature makes it an ideal material for applications where precise light control is needed, such as in backlit panels, display screens, and signage.

The light guide ABS plastic sheetis specifically designed to manage the diffusion and reflection of light through its structure. It can be used in various lighting solutions, ensuring uniform light distribution. It is also commonly known for its exceptional strength and impact resistance, making it a reliable choice for both industrial and consumer-grade applications.

1. Light Grey Color

The light grey color of the ABS plastic sheet makes it a suitable choice for a variety of industrial applications. This neutral tone provides a clean and modern look, while also reducing the appearance of dirt and wear over time. This color choice also complements a wide range of environments, from industrial spaces to consumer-facing applications.

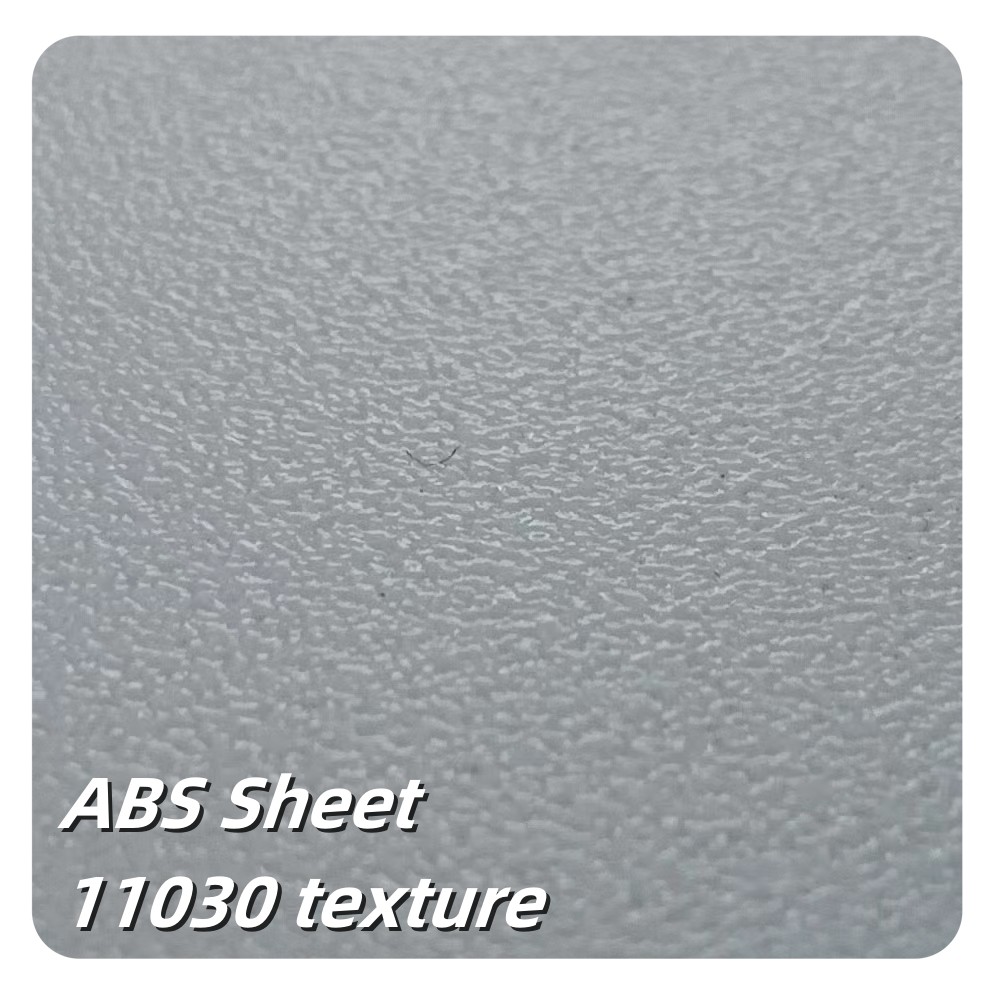

2. Texture for Enhanced Grip

The 11030 texture on the surface of the light guide ABS plastic sheet adds an important layer of grip. This textured surface enhances the sheet’s ability to provide a non-slip surface, which is especially beneficial for industrial settings where safety and stability are critical. The added texture also improves handling during installation or use, making it easier for workers to operate equipment and machinery that use these sheets.

3. High-Quality Material

At the core of the light guide ABS plastic sheet is its high-quality ABS material. ABS is known for its strength and durability. This type of plastic is highly resistant to physical impacts, meaning it can withstand harsh environments without easily cracking, breaking, or becoming deformed. Its durability makes it ideal for industrial applications, where long-lasting performance is essential.

4. Versatile Applications

One of the most remarkable aspects of the light guide ABS plastic sheet is its versatility. It can be used in a wide array of applications, including:

Machine Guards: Providing safety in industrial environments by protecting operators from moving parts.

Equipment Housing: Serving as a robust casing for sensitive machinery and equipment, offering both protection and aesthetic appeal.

Automotive Parts: Its strength and lightness make it perfect for manufacturing automotive components such as dashboards, interior panels, and exterior trims.

Signage and Display Panels: Due to its light-guiding properties, this material is often used in backlit signage and LED displays.

5. Easy to Fabricate

The light guide ABS plastic sheet is not only durable but also highly adaptable. It is easy to fabricate and can be cut, drilled, bent, and molded to meet the needs of specific projects. This flexibility makes it a preferred material for manufacturers and designers who need to create customized solutions for their clients. Whether it is a custom-designed machine guard or a uniquely shaped display panel, the light guide ABS plastic sheet can be easily modified to fit the task.

6. Chemical and Moisture Resistance

Another standout feature of the light guide ABS plastic sheet is its excellent resistance to chemicals and moisture. This makes it a great choice for industrial applications that require frequent exposure to harsh environments. Whether it is for factory machinery or outdoor signage, the ABS plastic sheet remains durable and resistant to water, oils, and other chemicals commonly found in industrial settings.

1. Automotive Industry

The light guide ABS plastic sheet is often used in the automotive industry for making high-performance parts that require durability and strength. Its ability to withstand impact while maintaining a sleek appearance makes it ideal for automotive interiors, such as dashboard panels, trims, and lighting components.

2. Industrial and Commercial Use

Manufacturers and industrial operators value the light guide ABS plastic sheet for its ability to endure harsh working conditions. The sheet is often used for machine guards, housing for industrial equipment, and protective panels. The material’s chemical and moisture resistance ensures that it maintains integrity and performance even when exposed to challenging environments.

3. Display and Signage

For businesses and advertising agencies, light guide ABS plastic sheets offer an ideal solution for backlit displays. Their ability to diffuse light evenly ensures that text, logos, or images are visible even in low-light conditions. Whether for retail signage, billboards, or LED panels, this material provides a reliable and effective solution for bright, visible displays.

4. Electrical and Electronics Enclosures

The light guide ABS plastic sheet is also used for the production of enclosures and housings for electrical and electronic components. The material’s excellent insulating properties make it a safe choice for protecting sensitive electronic parts from electrical interference, while its robust structure ensures longevity and durability in demanding environments.

When considering materials for industrial or commercial applications, there are several options available. However, the light guide ABS plastic sheet stands out for several key reasons:

1. Durability

Compared to many other plastics, ABS is known for its exceptional impact resistance. While materials like acrylic or polycarbonate may crack or shatter upon impact, ABS plastic tends to maintain its integrity under pressure.

2. Light Transmission

What sets the light guide ABS plastic sheet apart is its ability to guide and diffuse light effectively. Unlike solid or opaque plastic sheets, ABS plastic sheets engineered for light transmission provide uniform light diffusion, making them ideal for use in signage and backlit applications.

Q1: What are the benefits of using a light guide ABS plastic sheet in industrial settings?

The light guide ABS plastic sheet provides excellent impact resistance, chemical and moisture resistance, and is easy to fabricate. Its ability to guide light effectively also makes it ideal for applications requiring backlit panels or signage.

Q2: How easy is it to fabricate a light guide ABS plastic sheet?

The light guide ABS plastic sheet is highly adaptable and can be easily cut, drilled, bent, and molded. This flexibility makes it suitable for a wide range of custom projects.

Q3: What industries use light guide ABS plastic sheets?

Industries such as automotive, machinery manufacturing, electrical, and signage rely on light guide ABS plastic sheets for their durability, versatility, and ability to guide light effectively in backlit applications.

Q4: How does the light guide ABS plastic sheet compare to other materials like acrylic?

While acrylic offers good clarity and impact resistance, ABS plastic sheets provide better durability and chemical resistance. Additionally, ABS plastic tends to be more cost-effective while still delivering high performance.

Q5: Can the light guide ABS plastic sheet be used outdoors?

Yes, the light guide ABS plastic sheet is resistant to moisture and chemicals, making it suitable for outdoor applications, such as signage and machine housing.

The light guide ABS plastic sheet is a versatile, durable, and cost-effective material that has found widespread use in various industries. Its high-quality construction, ease of fabrication, and excellent performance in harsh environments make it a top choice for applications ranging from automotive components to industrial machinery. Whether you're looking for a material that can withstand the rigors of industrial applications or one that can effectively guide light for signage and displays, the light guide ABS plastic sheet offers a solution that meets your needs.