Views: 0 Author: Site Editor Publish Time: 2025-01-24 Origin: Site

Colored ABS plastic sheets are a versatile and widely used material in a variety of industries, thanks to their durability, flexibility, and aesthetic appeal. Whether for industrial applications, consumer products, or creative projects, these sheets offer an exceptional combination of strength and visual appeal, making them a popular choice in manufacturing. In this article, we’ll explore what colored ABS plastic sheets are, the different types available, their key features, and the wide range of applications that make them indispensable in modern industries.

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer that combines three distinct monomers: acrylonitrile, butadiene, and styrene. These three components give ABS plastic its unique set of properties, including impact resistance, high tensile strength, and heat resistance. ABS plastic sheets are made by extruding or molding this polymer into large, flat panels that can then be cut, shaped, and used for various applications. One of the key benefits of ABS plastic sheets is their ability to be colored, which gives them versatility for use in both functional and decorative applications.

Colored ABS plastic sheets are available in a wide range of colors, which makes them suitable for applications that require not only functionality but also aesthetic appeal. These sheets are used in manufacturing, design, and consumer goods, among many other sectors.

Colored ABS plastic sheetsoffer a variety of benefits and features that make them ideal for different industries. Here’s an overview of some key features of ABS plastic sheets, including the Light Grey ABS Plastic Sheet, which is particularly popular in industrial settings.

1. Light Grey Color for Modern Aesthetic

The Light Grey ABS Plastic Sheet is a common color choice in industrial environments due to its clean, professional, and modern appearance. It is ideal for a range of uses, including machine guards, equipment housings, and automotive parts. The light grey color provides a neutral base that is easy to pair with other colors and is less likely to show dirt and scratches compared to darker colors.

2. Texture for Enhanced Grip

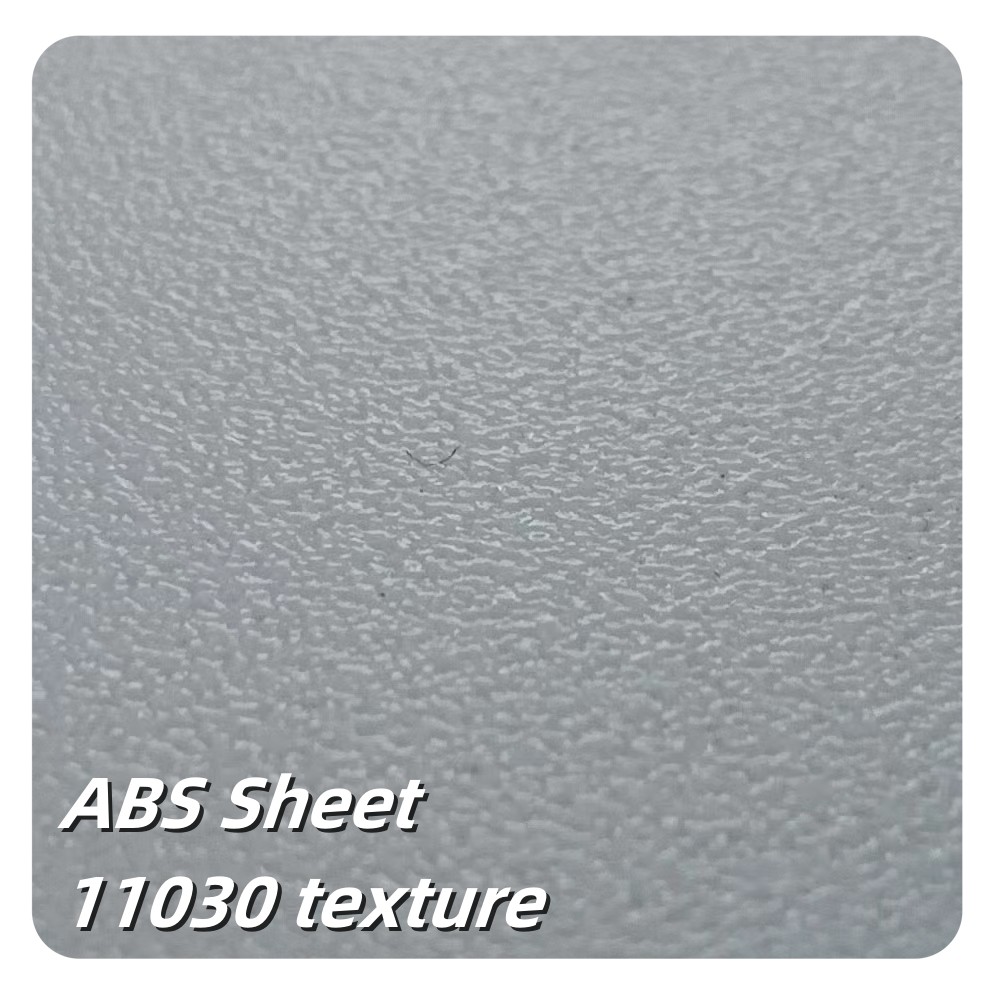

Some ABS plastic sheets, like those with the 11030 texture, have a textured surface that enhances grip, making them particularly suitable for industrial environments where safety and slip resistance are important. These textured sheets are commonly used for floors, walkways, and areas that require additional traction to reduce the risk of slipping. The 11030 texture provides a non-slip surface while maintaining the sheet's aesthetic quality.

3. High-Quality Material

Colored ABS plastic sheets are crafted from high-quality raw materials, ensuring that they have excellent strength and durability. These sheets are designed to withstand the rigors of various environments, including industrial settings, automotive applications, and consumer products. The material’s inherent impact resistance makes it perfect for applications where the sheet might be subject to physical stress or exposure to harsh conditions.

4. Chemical and Moisture Resistance

ABS plastic sheets, including colored varieties, are highly resistant to chemicals and moisture. This makes them a great option for environments where exposure to cleaning chemicals, solvents, or moisture is common. For example, they are frequently used in food processing areas, laboratory equipment, and automotive parts that may come into contact with fluids or chemicals.

5. Easy to Fabricate

One of the major advantages of ABS plastic sheets is their ease of fabrication. These sheets can be easily cut, drilled, bent, and molded to meet specific project requirements. Whether you’re creating custom housings for electronics, decorative panels, or parts for machinery, ABS plastic sheets offer the flexibility needed to make precise modifications.

6. Durable and Long-Lasting

Unlike some other plastic materials, ABS plastic sheets are highly durable and resistant to wear and tear. They have a longer lifespan than other materials like PVC or polystyrene, making them a cost-effective choice in the long term. The Light Grey ABS Plastic Sheet, for example, is especially known for its resistance to UV degradation and its ability to maintain its structural integrity over time.

7. Customization Options

Colored ABS plastic sheets come in a variety of colors, allowing manufacturers to choose the exact shade that meets their needs. Customization can also include different surface textures, such as matte, glossy, or the 11030 texture mentioned earlier. This level of customization helps businesses create products that align with their brand identity or specific functional requirements.

Colored ABS plastic sheets are used in a wide range of industries due to their strength, versatility, and aesthetic properties. Below are some of the most common applications of these sheets.

1. Industrial Applications

The Light Grey ABS Plastic Sheet is commonly used in industrial settings for applications like:

Machine Guards: ABS plastic sheets provide a durable, impact-resistant barrier that can protect machines and operators in industrial environments.

Equipment Housing: Due to their strength and chemical resistance, ABS plastic sheets are often used to house electrical and mechanical equipment.

Automotive Parts: In the automotive industry, ABS plastic sheets are used for interior panels, dashboard components, and other non-structural parts.

2. Signage and Display Panels

Colored ABS plastic sheets are ideal for creating signage, display panels, and promotional materials. Their ability to be easily fabricated and colored makes them popular in:

Backlit Panels: ABS plastic sheets can be used to create light diffusers and backlit panels, thanks to their excellent optical clarity and light guiding capabilities.

Exterior Signage: The UV resistance of ABS plastic sheets makes them a perfect choice for outdoor signage that needs to withstand exposure to the elements.

3. Consumer Goods and Household Products

Colored ABS plastic sheets are widely used in the production of consumer goods due to their versatility. Common household applications include:

Appliances: ABS plastic sheets are used in the housing of many home appliances, such as refrigerators, washing machines, and air conditioners, thanks to their strength and durability.

Toys and Gadgets: Their ability to be molded into intricate shapes makes ABS plastic sheets ideal for creating toys and small gadgets.

4. Architectural Applications

In architecture, ABS plastic sheets are used for a variety of purposes, including:

Decorative Panels: Colored ABS plastic sheets are used to create decorative elements in interiors, such as wall panels, partitions, and cladding.

Window Trim: The durability and UV resistance of ABS plastic sheets make them suitable for use in window trims and other exterior architectural elements.

5. Electrical Enclosures and Switchgear

Due to their electrical insulating properties and resistance to impact, ABS plastic sheets are commonly used in electrical enclosures and switchgear applications. They help protect sensitive electrical components from dust, moisture, and physical damage.

Colored ABS plastic sheets are incredibly versatile and durable materials used in a wide array of applications across multiple industries. Whether you need them for machine guards, signage, automotive parts, or household products, ABS plastic sheets offer the perfect combination of strength, impact resistance, and aesthetic appeal. The Light Grey ABS Plastic Sheet, with its modern color and additional textured surfaces like the 11030 texture, is particularly valuable in industrial environments where both functionality and visual appeal are important.

From industrial machines to consumer goods, colored ABS plastic sheets have proven to be an indispensable material, offering an effective and durable solution for various needs.